The Ultimate Guide to Choosing the Right Boiler Steel: A Complete Breakdown by Virgamet.com

The Ultimate Guide to Choosing the Right Boiler Steel: A Complete Breakdown by Virgamet.com

At Virgamet.com, we understand the significance of selecting the right boiler steel. Our experts have years of experience in the industry and have compiled their knowledge to create this ultimate guide. Whether you are a seasoned professional or a new buyer, this guide will provide you with in-depth information on the various types of boiler steel available, their qualities, and their applications.

With concise and accurate explanations, we will cover topics such as strength, durability, corrosion resistance, and temperature resistance. We will also delve into the different grades of steel and their respective properties. By the end of this guide, you will have a complete understanding of the factors to consider when selecting boiler steel that fits your specific needs.

Don’t compromise on the quality of your boiler steel. Trust Virgamet.com to equip you with the knowledge required to make the right decision every time.

Importance of choosing the right boiler steel

Choosing the right boiler steel is crucial for the efficiency, longevity, and safety of your boiler steelvirgamet.com. The wrong choice can lead to increased maintenance costs, decreased performance, and even catastrophic failures. Therefore, it is essential to consider several factors before making a decision.

Firstly, the strength of the boiler steel is of utmost importance. The steel should be able to withstand the high pressure and temperature conditions within the boiler without deforming or cracking. Additionally, it should have excellent durability to ensure a long lifespan and minimize the need for frequent replacements.

Corrosion resistance is another critical factor to consider. Boilers are often exposed to high levels of moisture and chemicals, which can cause corrosion and reduce the structural integrity of the steel. Choosing a steel with high corrosion resistance will protect your boiler from premature failure and ensure its longevity.

Temperature resistance is also essential. Boilers operate at high temperatures, and the steel used should be able to withstand these extreme conditions without losing its mechanical properties. It should not soften or deform under high temperatures, as this can compromise the safety and efficiency of the boiler.

Factors to consider when choosing boiler steel

When selecting boiler steelvirgamet.com, it is crucial to consider the specific requirements of your boiler. Different boilers have different operating conditions, and the steel chosen should be able to meet these requirements effectively.

One of the primary factors to consider is the maximum operating temperature of the boiler. This will determine the type of steel that can withstand the specific temperature range without losing its properties. The temperature resistance of the steel should be carefully matched with the operating conditions to ensure optimal performance and safety.

Another crucial factor is the pressure rating of the boiler. The steel used should have sufficient strength to withstand the internal pressure without deforming or rupturing. Different steel grades have different strengths, and it is essential to choose one that meets the required pressure rating.

Apart from temperature and pressure, factors such as corrosion resistance, weldability, and formability should also be considered. The steel should be resistant to corrosion from the specific chemicals present in the boiler environment. It should also be easy to weld and form, allowing for efficient manufacturing and maintenance processes.

Different types of boiler steel

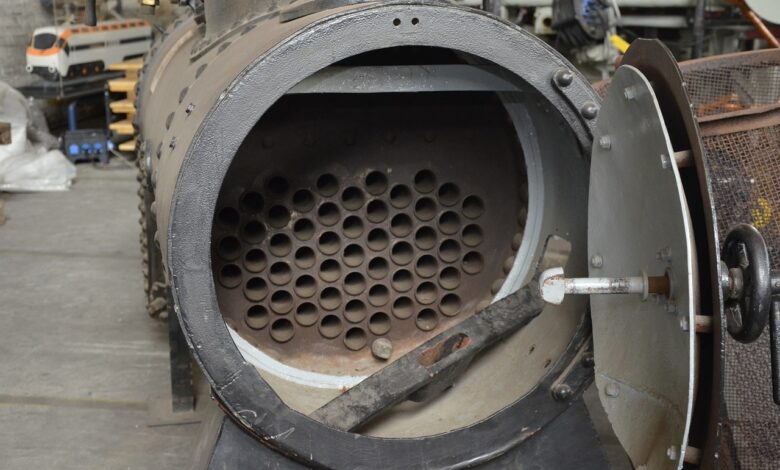

Several types of boiler steel are available, each with its own unique properties and applications. Understanding the differences between these types will help you make an informed decision about which one is most suitable for your boiler.

One common type of boiler steel is carbon steel. This type of steel is widely used in boilers due to its high strength and excellent formability. Carbon steel is affordable and readily available, making it a popular choice for many boiler applications. However, it is susceptible to corrosion and may require additional corrosion-resistant coatings.

Another type of boiler steel is alloy steel. Alloy steels are made by adding various alloying elements to enhance specific properties. For example, chromium can improve corrosion resistance, while molybdenum can increase temperature resistance. Alloy steels offer a balance of strength, durability, and corrosion resistance, making them suitable for a wide range of boiler applications.

Stainless steel is also commonly used in boilers, thanks to its excellent corrosion resistance and temperature resistance. It contains a high percentage of chromium, which forms a protective oxide layer on the surface, preventing corrosion. Stainless steel is particularly suitable for boilers that handle corrosive fluids or operate at high temperatures.

Common grades and specifications of boiler steel

Boiler steel is available in various grades and specifications, each designed for specific applications and operating conditions. Understanding the different grades and their properties will help you choose the most appropriate steel for your boiler.

One commonly used grade is ASTM A516. This grade is often used for moderate and lower temperature applications and offers excellent weldability and toughness. It has a minimum tensile strength of 70 ksi (483 MPa) and a minimum yield strength of 38 ksi (262 MPa), making it suitable for a wide range of boiler applications.

Another popular grade is ASTM A387. This grade is specifically designed for high-temperature applications and offers excellent temperature resistance and corrosion resistance. It is commonly used in boilers that operate at elevated temperatures and under high-pressure conditions.

In addition to these grades, there are various other specifications available, such as ASTM A285, ASTM A204, and ASTM A515. These specifications cover a wide range of temperature and pressure ratings, allowing you to choose the most suitable steel for your specific boiler requirements.

Testing and certification of boiler steel

When choosing boiler steel, it is important to ensure that it meets the necessary quality standards and regulations. Testing and certification play a crucial role in verifying the properties and performance of the steel.

One common test conducted on boiler steel is the tensile test. This test measures the strength and ductility of the steel by subjecting it to tension until it fractures. The results of this test provide valuable information about the mechanical properties of the steel, such as its yield strength, tensile strength, and elongation.

Another important test is the impact test, which measures the steel’s ability to absorb energy under impact loading. This test is particularly important for boiler steel, as it determines its toughness and resistance to brittle fracture. It involves striking a notched specimen with a pendulum and measuring the energy absorbed during the fracture.

Certification is also essential to ensure that the boiler steel meets the necessary quality standards. Various organizations, such as the American Society of Mechanical Engineers (ASME), provide certification programs for boiler steel. These certifications indicate that the steel has been tested and meets the required standards for use in boilers.

Comparison of boiler steel suppliers

Choosing the right supplier is as important as selecting the right boiler steel. The supplier should have a good reputation, a wide range of products, and excellent customer service. Comparing different suppliers will help you find the most reliable and reputable one.

When comparing suppliers, consider factors such as the range of products they offer, their experience in the industry, and their track record of delivering high-quality materials. Look for suppliers that have a strong presence in the market and have built a reputation for providing reliable and durable boiler steel.

It is also important to consider the supplier’s customer service and support. A supplier that offers prompt and efficient customer service can greatly enhance your experience and ensure that you receive the assistance you need throughout the purchasing process.

Additionally, consider the supplier’s delivery capabilities and lead times. Timely delivery is crucial to avoid project delays and ensure that the boiler steel is available when needed. Look for suppliers that have a robust logistics network and can deliver the materials on time.

Case studies: Successful applications of different boiler steel grades

To further illustrate the importance of choosing the right boiler steel, let’s explore some case studies of successful applications using different steel grades.

In one case, a power plant required a boiler steel that could withstand high temperatures and pressures. They chose ASTM A387 grade 11, which offers excellent temperature resistance and corrosion resistance. The boiler has been operating successfully for several years, with minimal maintenance requirements.

In another case, a chemical processing plant needed a boiler steel that could resist corrosion from the harsh chemicals present in the process. They opted for stainless steel grade 316, which offers superior corrosion resistance. The boiler has been in operation for over a decade without any significant corrosion issues.

These case studies highlight the importance of selecting the right boiler steel for specific applications. By considering the operating conditions and requirements, you can choose a steel grade that will ensure optimal performance and longevity.

Tips for maintaining and extending the lifespan of boiler steel

Once you have chosen the right boiler steel, proper maintenance is crucial to ensure its longevity and performance. Here are some tips for maintaining and extending the lifespan of your boiler steel:

- Regular inspections: Regularly inspect the boiler for any signs of corrosion, leakage, or damage. Address any issues promptly to prevent them from escalating.

- Proper cleaning: Clean the boiler regularly to remove any debris or deposits that can lead to corrosion or reduced efficiency. Follow the manufacturer’s guidelines for cleaning procedures and recommended cleaning agents.

- Adequate water treatment: Proper water treatment is essential to prevent corrosion and scale formation in the boiler. Use the appropriate water treatment chemicals and follow the recommended dosages.

- Control water chemistry: Monitor the water chemistry parameters, such as pH and dissolved oxygen levels, to ensure they are within the recommended range. Adjust the water chemistry as necessary to prevent corrosion and scale formation.

- Regular maintenance: Schedule regular maintenance activities, such as cleaning, inspection, and servicing, as recommended by the manufacturer. This will help identify and address any potential issues before they escalate.

- Train operators: Ensure that the boiler operators are properly trained and knowledgeable about the specific requirements of the boiler steel. Provide them with the necessary training and resources to operate the boiler safely and efficiently.

By following these maintenance tips, you can maximize the lifespan of your boiler steel and ensure optimal performance throughout its service life.

Conclusion: Making the right choice for your boiler steel needs

Choosing the right boiler steel is a critical decision that can have a significant impact on the performance, efficiency, and safety of your boiler. By considering factors such as strength, durability, corrosion resistance, and temperature resistance, you can make an informed decision that meets your specific requirements.

At Virgamet.com, we understand the importance of selecting the right boiler steel. Our comprehensive guide has provided you with in-depth information on the various types of boiler steel available, their qualities, and their applications. We have covered topics such as different grades and specifications, testing and certification, comparison of suppliers, and maintenance tips.

Don’t compromise on the quality of your boiler steel. Trust Virgamet.com to equip you with the knowledge required to make the right decision every time. With our expertise and wide range of products, we can help you find the perfect boiler steel that meets your specific needs. Contact us today to get started on your journey to choosing the right boiler steel.

2 Comments